How many Types of Steel Rule and it’s name | Use of Calliper’s and Precaution’s | Flexible Rule | How many Types of Steel Rule and it’s name

How many Types of Steel Rule and it’s name

Table of Contents

Measuring Tools

Procure a metre stick or a measuring tape. The metre stick or the tape has a scale and in some cases even two scales, i.e., the English and the metric scale. The metric scale, which has the smaller divisions and goes up to 100, (or for tapes even to 150) is the one which you have to use for your measurements in science. The other rulers available in the market are made of wood or plastic and are used by the school children.

According to the decimal system, a metre is subdivided into 10 equal parts, called decimetres and written as dm.

Each decimetre is again subdivided into 10 equal parts, called centimetres, and written as cm.

Finally, the centimetre is again divided into 10 equal parts, called millimetres, and written as mm.

Therefore,

1 m = 10 decimetres

= 100 centimetres

= 1000 millimetres

1 m = 10 dm

= 100 cm

= 1000 mm

1 mm = 0/001 m

1 cm = 0.01 m

1 dm = 0.1 m

The other side has markings in inches; an inch may be divided into eight, sixteen, thirty -two or sixty -four

divisions.

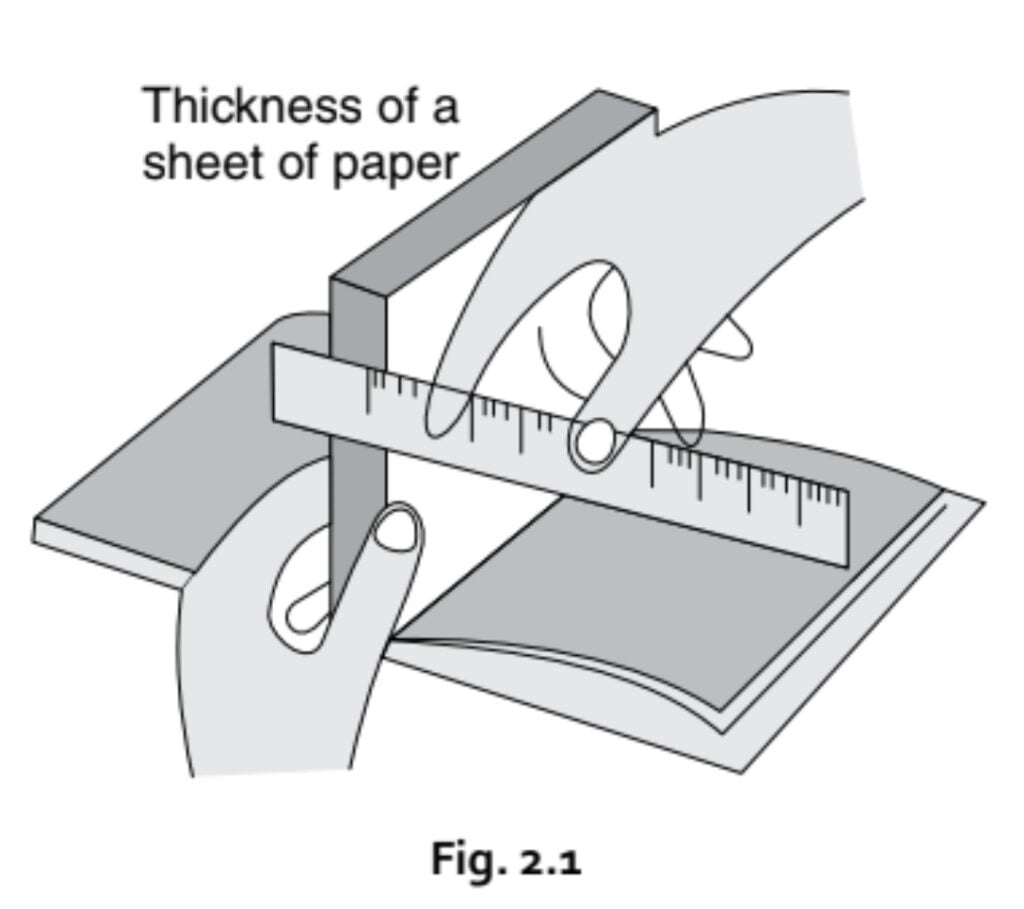

- Try to find out the thickness of one page of your book.

You are supposed to use your ruler only and a bit of brain. (Fig. 2.1) - With any of the rulers it is not possible to measure the

thickness of the sheet of a paper. It is so thin that the

markings may not give the correct measurement. - 100 sheets of the book may be taken. The thickness of

these sheets may be found out with the help of any of the simple rulers. Measure the thickness of 100 sheets and then calculate the thickness of one sheet. How accurate will be the measurement ?

12″ size are most widely used. Foot rules indicate inches or millimetres or both, and division of inches and millimetres. Generally, foot rules indicate division markings at a distance of an inch. One inch is divided into 8 equal parts. In this way, each marking represents 1/8th of an inch, known as soot. This 1/8th is divided into two parts making it 1/16th of an inch. Further, this 1/16th is divided making it 1/32th and 1/64th part of an inch.

This foot rule can be used to measure minimum up to 1/64th of an inch. The graduation can be indicated on one edge or both the edges of the foot rule. Some foot rules have signs on one edge only and on the other

edge there is marking of metric system. These foot rules are more useful as we can measure in British as

well as metric system. In the edge where millimetre graduation is indicated, markings at every centimetre are

indicated. Each centimetre is divided into ten equal parts to indicate a millimetre. Each sign of millimetre is

also divided into two equal parts. Thus, we can measure up to ½ millimetre from this edge.

How many Types of Steel Rule and it’s name

Types of foot rules

- Flexible steel rule

- Hook rule

- Narrow rule

- Shrink rule

- Short rule

- Key-set rule

- Calliper rule

- Steel tape rule

- Folding rule

- Canvas tape rule

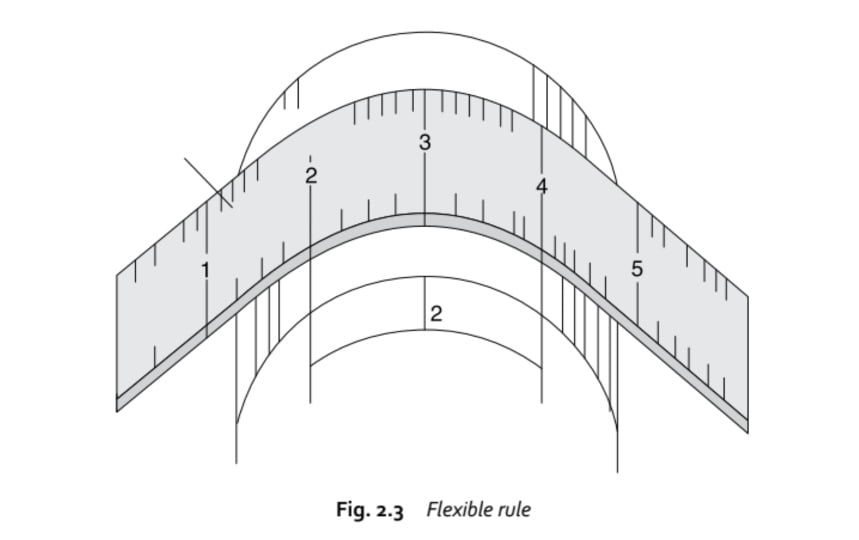

Flexible Rule

This rule is used for measuring spherical or hemispherical objects. These are 6″ to 12≤”in size. These are made

from spring steel sheet of 1/64″ thickness so that it attains elasticity.

This rule contains measurement both in inches and millimetres

First two inches are divided into 32 equal parts and the third inch is divided into 64 equal parts. On rest of

the rule each inch is divided into 8 equal parts.

In the same way, other side of the rule markings indicate centimetres. Each centimetre is divided into ten

equal parts ,i.e., one millimetre. This part is further divided into two equal parts.

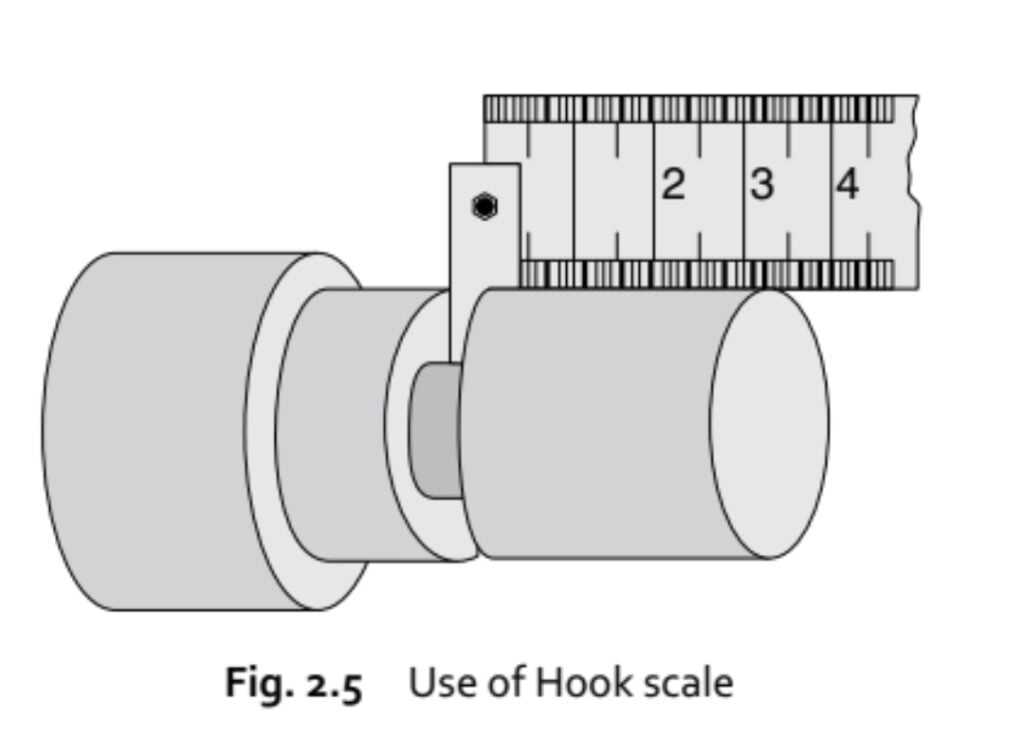

Hook Rule (Fig. 2.8)

This rule is also made of spring steel with a hook attached to its one end. It is used to measure special type of spaces. Suppose there is a groove inside a hole and we have to measure the remaining part (leaving aside the groove) or to measure the remaining part of a round job leaving aside its step.

Hook rule can be of the size of 6″ 12″ or more.

Narrow Rule

Narrow rules are like a flexible rule, it is smaller and its breadth is narrow, about 6 mm. A clip is attached to it with which it is kept in the pocket. Both inches and millimetres are marked on it.

Generally, it is used to measure slot, slit, or thin pipe.

ITI Result 2021| आईटीआई result कैसे Online चेक करते है 1st & 2nd year

Shrink Rule

This rule is generally used by pattern makers while making patterns in order to allow for the shrinkage of the metal in which the pattern is to be cast. The marking is slightly more than actual,

in proportion; because of its enlarged size patterns get shrink allowance.

Short Rule

This rule is used by the machinists and die-makers for measuring small gaps, slots, etc. It is a set of small rules, made of steel leaves.

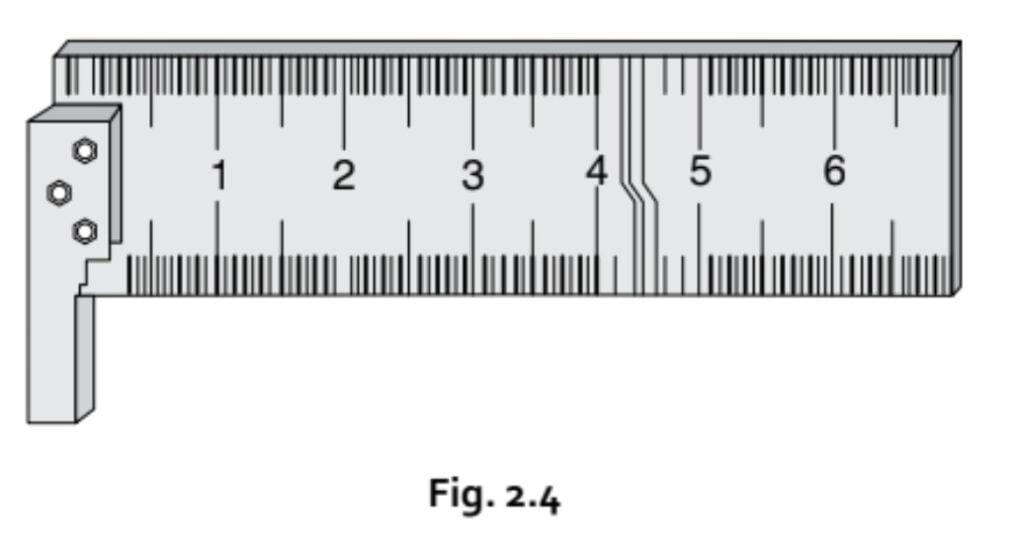

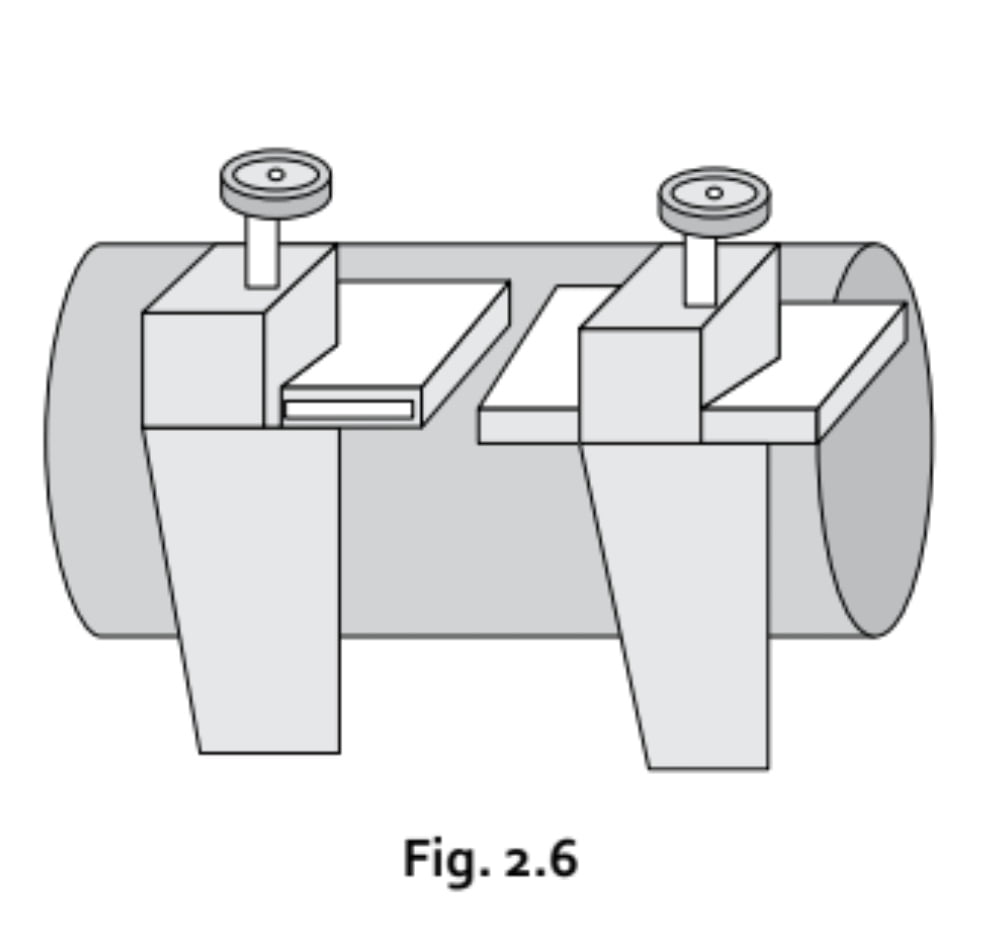

Key Seat Rule (Fig. 2.6)

Its shape is somewhat different from an ordinary rule. It is almost like angle iron, having both beams at 90° Spherical and hemispherical jobs which cannot be measured with ordinary rules because this can be adjusted on those round things easily. These are particularly made to measure marking of key way rules one is plain and the other contains marking of inches or millilitres.

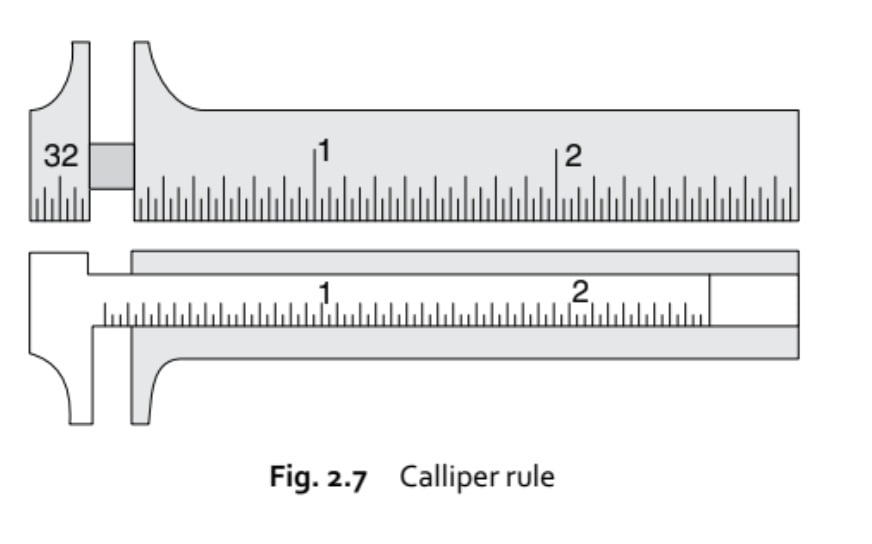

Calliper Rule (Fig. 2.7)

This is a special type of rule. It is used to take inside and outside measurements of the round articles. A narrow rule and a rule of normal breadth are used in it. In the broader rule, the narrow rule can be slided. Both the rules have a jaw on one end. The tip is so small that it can go into a hole. A screw is fixed on the broader rule with which the narrow rule can be adjusted and can be locked in position.

These rules contain both the Metric system and the British

systems of graduation.

Steel Tape Rule (Fig. 2.8)

It is often difficult or rather impractical to carry long foot rules. For the purpose of convenience steel tape rules are available. This is made of spring steel and is elastic. It can be rolled and packed in a round tiny box (case). Its breadth is 1″ and length is 6″. It contains inch as well as millimetre graduation.

Canvas Tape (Fig. 2.9)

This rule is used for measuring greater lengths. This is made of a long canvas tape which can be rolled and packed in a small leather or steel box. A ring is attached to the one end. By pulling this ring we can pull out the tape. For folding it a small handle is provided. These tape rules are generally of 50 to 100 feet in length.

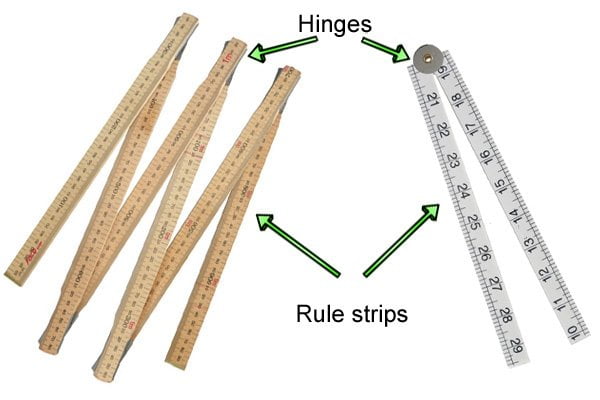

Folding Rule (Fig. 2.10)

This rule is made by joining four pieces of 6 inches. These pieces are either wooden or of steel. It is generally used by the carpenters and masons, by unfolding this rule we can take measurement up to 2 feet. When we fold it, it is reduced to 6″. Graduation in inches and millimetres is indicated on it.

MEASURING WITH THESE TOOLS

The method of using a try-square and a steel rule for accurate measurement is illustrated. For accurate readings,

it is necessary to read vertically and avoid errors arising out of parallax.

Some important points to be remembered while using the steel rule:

- Measurement should be taken by keeping the steel rule erect on the job and not by laying it down on

the job. - As far as possible measurement should be taken from the corner of the steel rule.

- Prevent the steel rule from getting rusted.

- Steel rules should be kept separate from other tools so that it does not get any scratches.

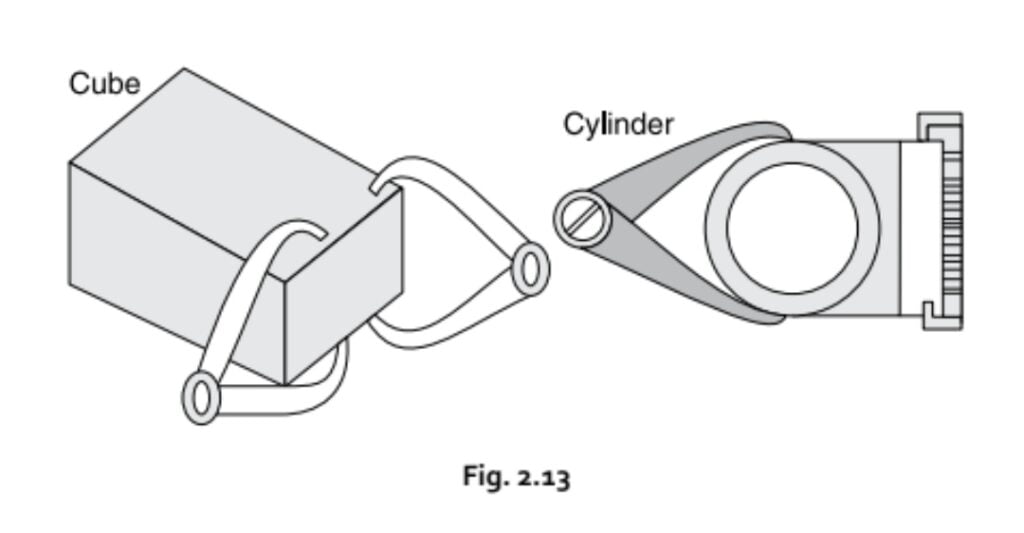

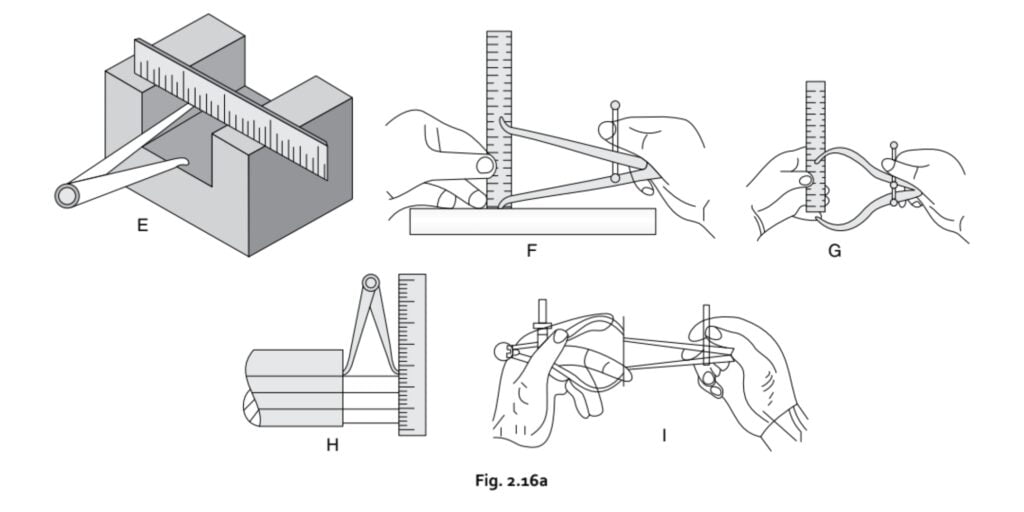

Measuring a cubical and cylindrical job (Fig. 2.13)

The points at the end of the legs are opened to cover the round shape. Between these legs the measurement

of the job is taken, for gauging inside diameters. It can also gauge the breadth and depth of a slot or slit groove

etc.

Inside Callipers

It has the points at the end of the legs turned outward instead of inward, so that it may be used of gauging inside diameters, but we can also gauge the breadth and depth of a slot or slit groove etc.

Use of Callipers and Precautions

- Select the callipers according to the job.

- Open the calliper according to the job.

- Set the calliper in such a manner that its legs have only a mild touch with

the job. - While opening and closing the calliper with firm joint it should be ensured

that we do not strike it on any other metal except wood. Otherwise its points

would be damaged and would not be able to measure correctly. - Spring callipers should be handled (picked up) in such a way that we are

able to move its nut with our thumb and finger. - After taking correct measurement we should read from the steel rule.

- Measurement with callipers should be taken to get actual measurement.

- Do not measure a fixed part on a moving machine, the calliper may fall down and get damaged.

- At times, for certain purpose, measurement has to be transferred from one calliper to another. In such

a case, ensure that the tips of the legs of both the callipers meet at the same point. - Do not tighten or loosen the joints of callipers.

Spring Callipers (Fig. 2.15)

The legs of spring callipers are made from suitable alloy steel, measuring faces properly heat treated and

hardened to a hardness of 65+50 HV. All the component parts are smoothly finished. The right part which

is made from carbon spring steel is properly hardened and tempered to a hardness of 0 to 520 HV and all

the components are manufactured and assembled in such a way as to achieve and maintain the smooth

adjustment and efficient operation.

EXERCISE

- In how many categories the tools used in the fitter trade have been divided? List them.

- What are the different types of foot rule? To what minimum extent graduation is indicated on the steel

foot rule ? - Name the different types of callipers?

- What is the method of taking measurement with outside and inside callipers?

- What function is performed by Jenny Calliper? How does it function? What is its other name?

- For what reason are the rough dimensions of the piece list or order-card transferred to the rough part

without over size in length? - What is the measuring accuracy that can be obtained: (a) with the steel straight edge and (b) the

sliding caliper? - What is the difference between the accuracy of measurement and accuracy of reading?

- Describe the sliding calliper that allows a measurmg accuracy up to 1/10th of a millimetre.

- How can measuring mistakes be avoided?

- How are measuring instruments protected against fall, shock, heat or rust?

How many Types of Steel Rule and it’s name

इसे भी पढ़े…

- Turner MCQ Question 1st Year Exam paper in hindi

- Turner Theory MCQ Question Answer in hindi

- Workshop & Calculation में पूछे जाने वाले बहुविकल्पिक प्रश्न 2021

- WSC 1st year MCQ Modal Question paper 2021

- Electrician 1st year MCQ in English & Hindi 2021

- 2nd Year Electrician Theory Objective Question 2021

- Diesel MCQ Question and Answer in Hindi 2021

- वेल्डिंग के 100 महत्वपूर्ण प्रश्न उत्तर